Reliability,endurance,cost effectiveness

Ideal Equipment for Your Mining and Dredging Project

What Is a Submersible Sand Dredge Pump?

Submersible dredge pumps are the ideal equipment for underwater dredging and sand mining tasks. Their applications are extensive, ranging from extracting and transporting sediments, slurry, and debris from riverbeds, lakes, ports, channels, and other aquatic bodies. Unlike traditional surface pumps, submersible dredge pumps operate fully submerged in water, delivering efficient performance in underwater environments without the need for external priming or suction systems.

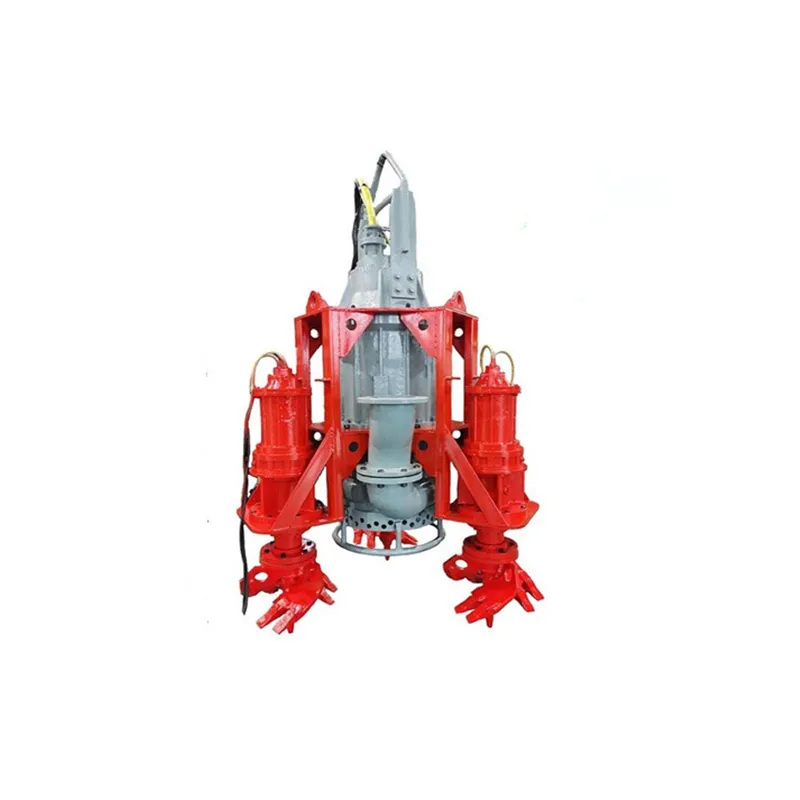

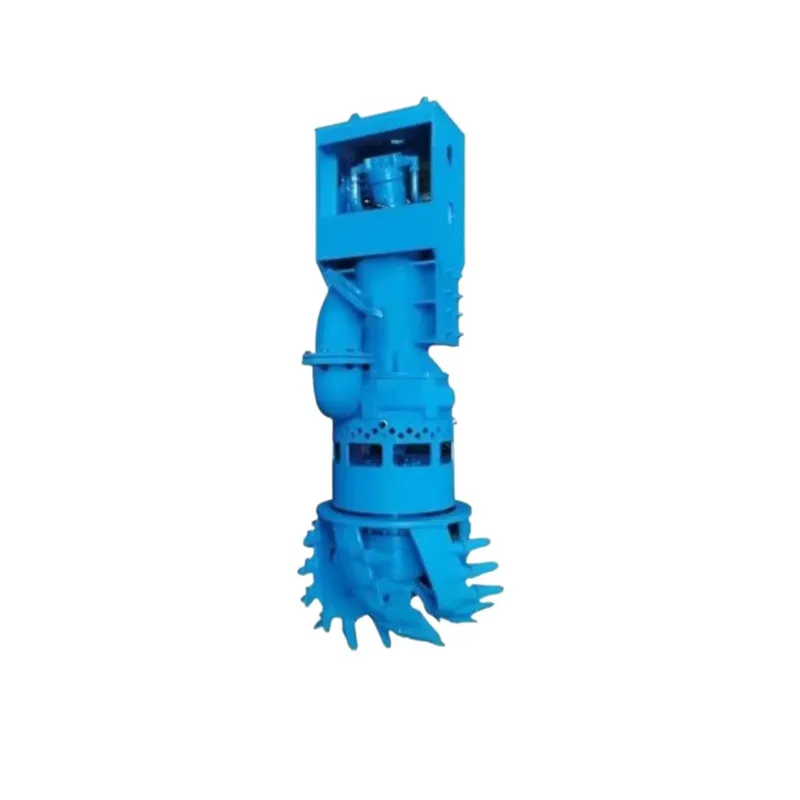

Submersible sand dredge pumps are categorized by power source into electric submersible sand dredge pumps and hydraulic submersible sand dredge pumps. These pumps consist of components such as the pump casing, impeller, shaft, motor. The impeller is installed within the pump casing and is rotated by the motor, generating suction to propel dredged materials. The motor is designed to be waterproof, preventing water ingress and ensuring the equipment’s safety and reliability.

Everflowing Pumps’ submersible sand dredge pumps are capable of handling various types of dredged materials, including sand, silt, soil, and rocks. To address wear and corrosion challenges, these pumps utilize wear-resistant impellers, high-chromium alloys, or special coatings in their structural materials. They can be applied in various dredging operations such as waterway construction and maintenance, deep dredging, land reclamation, environmental restoration, and mining. Submersible dredge pumps play a crucial role in sediment removal, promoting smooth navigation, and facilitating sustainable water utilization.

Send InquiryWhy Do We Choose to Use a Submersible Sand Dredge Pump?

The submersible sand dredge pump stands out as an ideal underwater dredging equipment due to its simplicity in installation, ease of operation, versatility, efficiency, and low maintenance requirements. These qualities make it a preferred choice for various dredging applications where simplicity, reliability, and performance are paramount.We take pride in delivering reliable and robust equipment that can handle even the toughest of dredging challenges.

- Submersible Design: Being submersible means that the pump can operate underwater without the need for additional support structures. This design simplifies the setup process as there’s no requirement for elaborate positioning or external support systems.

- Effortless Installation: Installing a submersible sand dredge pump typically involves lowering it into the water body where dredging is required. This process is relatively straightforward and doesn’t demand complex machinery or extensive technical expertise. Once lowered into place, the pump can immediately begin its operation.

- User-Friendly Operation: These pumps are designed with user convenience in mind. They often feature simple control interfaces that are easy to understand and operate. Users can start, stop, and adjust the pump’s settings with minimal effort, making it accessible even to operators with limited technical knowledge.

- Versatility: Submersible sand dredge pumps are versatile and can be used in various water environments, including rivers, lakes, ponds, and even industrial tanks or reservoirs. This versatility makes them suitable for a wide range of dredging applications, from small-scale residential projects to large-scale industrial operations.

- Efficiency: These pumps are specifically designed to handle abrasive materials like sand and sediment efficiently. Their robust construction and powerful motors enable them to effectively dislodge and transport sediment without clogging or experiencing significant wear and tear, ensuring consistent performance over time.

-

Low Maintenance: Submersible sand dredge pumps typically require minimal maintenance, reducing downtime and operational costs. Routine inspections and basic maintenance tasks such as cleaning and lubrication are usually sufficient to keep the pump in optimal working condition.

Electric Submersible Sand Dredge Pump

Electric submersible sand dredge pumps are driven by industrial electricity or generators

Electric Submersible Dredge Pump with Cutter Head

Get a free quote

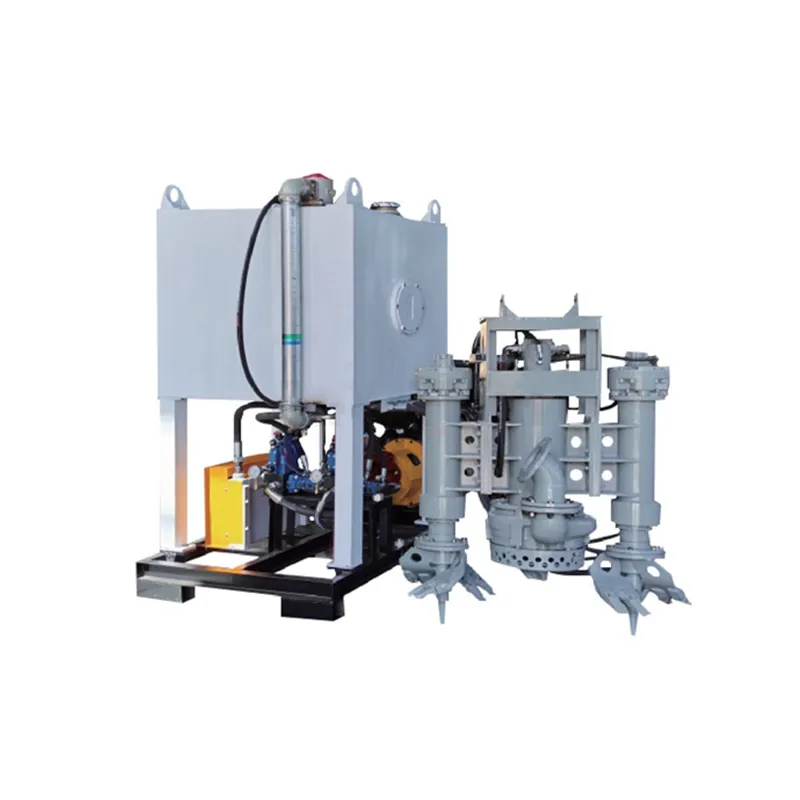

Large Flow Submersible Dredge Pump

Hydraulic Submersible Sand Dredge Pump

Hydraulic submersible sand dredge pumps are powered by hydraulic motors.Mounted on excavator or dredge platform.

Pump Accessories

Floating Dredge Pump Platform

Get a free quoteFloating dredge pump platform is designed to provide a stable working platform for suspending submersible dredge pump.

Everflowing platform is designed to be easily transportable by road and quickly assembled on site. All Platforms are equipped with a hoist frame and lifting tackle and provision for mounting a pump control panel. Platforms are sized according to the size and weight of the pump being used. Their small size makes them ideal for small dredging or basin cleaning projects.

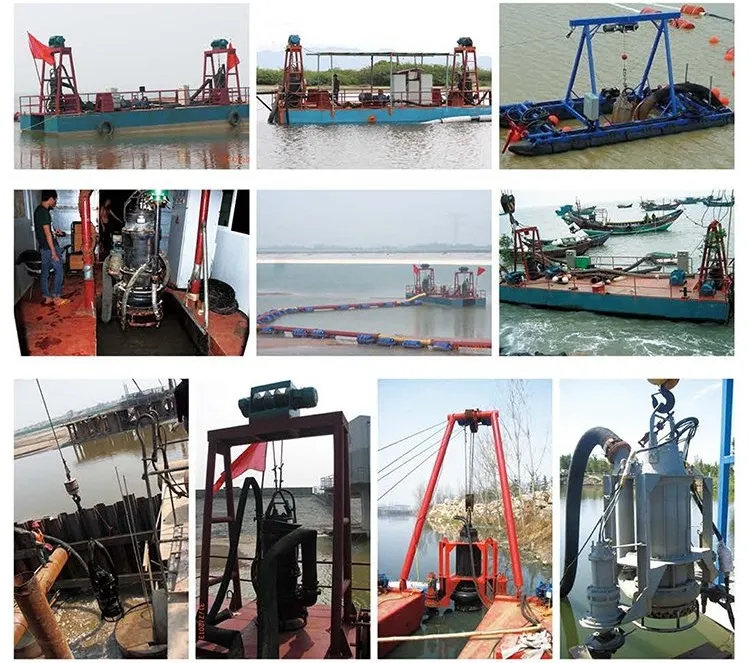

Sand Dredge Pump Application

Mining

Mineral extraction, excefficiently lifting valuable resources like ore sand,gold, and diamonds from underwater deposits

Dredging

Remove sand,slurry,sediment, silt, and debris from bodies of water to maintain navigable waterways, ports

.

Desilting

Rivers, lakes and reservoirs clean up,effectively remove sand,slurry,tailings and other solid

Industry

Handle abrasive fluids with solid,such as sand, ash slurry,coal slurry, chemical slurry and sediment

Applications of Everflowing Submersible Sand Dredge Pump

Dredging and Excavation: Widely used in dredging projects, these pumps remove impurities from rivers, lakes, and ports, playing a crucial role in maintaining waterways and reclaiming land. Their powerful suction capacity enhances dredging efficiency, even in deeper waters.

Mining and Mineral Processing: These pumps improve extraction efficiency and offer excellent wear resistance, making them vital in the mining industry for handling slurry containing solid particles.

Construction and Infrastructure Development: Used to remove water, sediment, and debris from construction sites, these pumps facilitate safe and efficient construction operations and are essential in infrastructure projects like bridges, tunnels, and dams.

Power Generation: Everflowing Submersible Dredge Pumps handle mortar efficiently, making them essential in thermal power plants for transporting ash from coal burning without blockages or other issues.

Industrial and Process Applications: These pumps find applications in various industries requiring pumping of abrasive slurries, including cement production, steel manufacturing, chemical processing, and wastewater treatment.

Get Your Custom Dredging and Pumping Solution

Work Video

Submersible Sand Dredge Pump Installation

- Vertical Installation: The submersible dredge pump is positioned vertically in the water column, usually suspended from a support structure or anchored in place. This installation type is often used in deep water or where the pump needs to reach a specific depth for efficient dredging.

- Automatic Coupling Installation:Mounting the coupling device at the bottom of the pool, allowing the pump to slowly descend along the guide rails until it is connected to the discharge pipe socket via the coupling flange.

- Floating Installation: The submersible dredge pump is mounted on a floating platform or vessel. This installation type allows for mobility and flexibility in dredging operations, especially in large water bodies or when dredging in different locations is required.

- Excavator Installation: The submersible dredge pump is installed using an excavator. This installation type is often used in smaller-scale dredging projects or in locations where access is limited, such as narrow waterways or remote areas.

The choice of installation type depends on factors such as water depth, site accessibility, project scale, and specific dredging requirements. It’s essential to carefully evaluate these factors and select the most suitable installation type to ensure efficient and successful dredging operations. Additionally, consulting with experienced dredging professionals and adhering to industry best practices can help ensure the optimal performance of the submersible dredge pump in the chosen installation type.

Submersible Sand Dredge Pump Selection

Choosing the right submersible dredge pump is crucial for the success of dredging operations. Here’s a concise guide to help you make informed decisions:

- Understand your dredging requirements: Consider material type, solid concentration, dredging depth, pumping capacity, and discharge distance and height requirements.

- Size and power: Ensure the pump has adequate capacity and power to handle operational challenges.

- Solid handling capability: Look for impeller designs and clearance adjustments suitable for handling various solid sizes and concentrations.

- Material construction: Choose durable, corrosion-resistant materials such as high-chrome alloys or stainless steel based on operational requirements to extend the pump’s lifespan.

- Efficiency and energy consumption: Prioritize pumps with efficient designs to minimize energy losses and operating costs.

- Submersible depth rating: Select pumps with appropriate sealing mechanisms, cable selection, and motor designs to meet the required submersion depth.

- Pump control and monitoring: Consider optional features such as remote control, overload protection, temperature monitoring, and vibration sensors to enhance operational safety and efficiency.

About Us

Everflowing Pump was founded by a team of highly skilled engineers specializing in sand pumping and dredging projects, with extensive practical experience in sand extraction, mining, and dredging operations. In their work, they encountered many challenges such as rapid pump wear, low efficiency, short discharge ranges, and frequent shutdowns. They recognized the urgent need for more reliable and higher-performing equipment. To address these industry issues, they developed wear-resistant, high-efficiency, high-lift sand pumps. These advancements not only improved the performance and reliability of the equipment but also provided tailored solutions for the specific demands of complex engineering environments. Over time, Everflowing Pump has earned a reputation for innovation and leadership, becoming a trusted partner in dredging and mining field.

At Everflowing Pump, our mission is to provide reliable, efficient, and durable pump solutions that meet the real-world challenges faced by dredging professionals. We believe in continuous innovation, driven by a deep understanding of industry needs.

Send InquiryFAQ

Submersible dredge pumps are the ideal equipment for underwater dredging and silt removal tasks. Their applications are extensive, ranging from extracting and transporting sediments, slurry, and debris from riverbeds, lakes, ports, channels, and other aquatic bodies. Unlike traditional surface pumps, submersible dredge pumps operate fully submerged in water, delivering efficient performance in underwater environments without the need for external priming or suction systems.

Submersible sand dredge pumps are categorized by power source into electric submersible sand dredge pumps and hydraulic submersible sand dredge pumps. These pumps consist of components such as the pump casing, impeller, shaft, motor. The impeller is installed within the pump casing and is rotated by the motor, generating suction to propel dredged materials. The motor is designed to be waterproof, preventing water ingress and ensuring the equipment’s safety and reliability.

A dredge pump is a type of pump used in dredging operations to remove material such as sediment, sand, and other debris from the bottom of bodies of water like rivers, lakes, and oceans.

The dredge pump works by creating suction or using an impeller to move water and sediment from the bottom of the water body into a pipeline or other container. The material can then be transported to a different location or disposed of as needed.

Dredge pumps come in various sizes and types, depending on the size and nature of the material being dredged, as well as the distance it needs to be transported. They can be powered by electricity, diesel engines, or hydraulic systems, and can be mounted on a variety of vessels such as barges, dredgers, or excavators.

Overall, dredge pumps are an essential component of many dredging operations, and they help to keep waterways clear and navigable, support marine construction projects, and protect coastal communities from erosion and flooding.

A dredge pump is a type of centrifugal pump used to transport sand, mud, and other solids in mining, construction, and environmental applications. The pump works by converting mechanical energy from a motor or engine into fluid energy, which moves the dredged material through a pipeline or hose.

The dredge pump consists of an impeller, volute casing, and suction inlet. The impeller is a rotating component with curved blades that spin inside the volute casing, which is a stationary housing that directs the flow of fluid. The suction inlet is a port where the material enters the pump.

When the impeller rotates, it creates a centrifugal force that moves the fluid and solids outward from the center of the impeller. This force creates a low-pressure zone in the center of the impeller, which draws the material into the pump through the suction inlet. As the material enters the pump, it is mixed with the fluid and moved towards the volute casing.

Once the material reaches the volute casing, the fluid and solids are directed towards the discharge outlet, where they exit the pump and are transported through the pipeline or hose. The discharge pressure of the pump depends on the design of the impeller and volute casing, as well as the speed of the motor or engine driving the pump.

The distance that a dredge pump can transport sand depends on several key factors. Here are some important considerations:

Dredging Depth: Dredging depth refers to the depth at which the pump extracts sand from the surface to the seabed.

Sand Characteristics: The nature of the sand being dredged is crucial. Depending on the particle diameter and density of the sand, finer sand may be pumped over longer distances compared to coarse or heavy sand.

Sediment Concentration: The concentration of sand and sediment in the water will affect the pump’s transport distance.

Altitude Changes: Significant changes in altitude along the transportation route can impact the pump’s transport distance. For example, pumping sand uphill requires more energy and may limit the distance.

Pipe Diameter and Material: Different pipe materials and diameters used for transportation result in varying friction and resistance, affecting the transport distance.

Dredge Pump Type: The type of dredge pump used plays a crucial role in determining its sand transport distance. High-head dredge pumps can transport sand over longer distances.

Dredge Pump Size and Power: The size and power of the dredge pump also influence its sand transport capacity. Larger, more powerful dredge pumps can transport sand over greater distances.