Everflowing Pumps ,Dredging the World

Leading Manufacturer of Sand Dredge Pump

We are a world leading manufacturer of sand dredge pump, meeting the needs of our customers with excellent product quality, durability, and efficiency.

Our focus on quality, innovation, customer service, and effective marketing can help you maintain a competitive advantage and drive sustained success in dredging project.

Our horizontal dredge pumps are designed for efficient and high-volume mud dredging operations, while the vertical dredge pumps are suitable for applications where space is limited. The submersible dredge pumps are ideal for underwater dredging tasks. We take pride in delivering reliable and robust equipment that can handle even the toughest of dredging challenges.

Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry. Whether you are involved in mining, construction, environmental remediation, or any other field requiring efficient mud dredging solutions, our range of pumps is designed to meet your needs. Contact us today to discuss how our dredge pumps can enhance your operations and make your projects more efficient and effective.

Send Inquiry

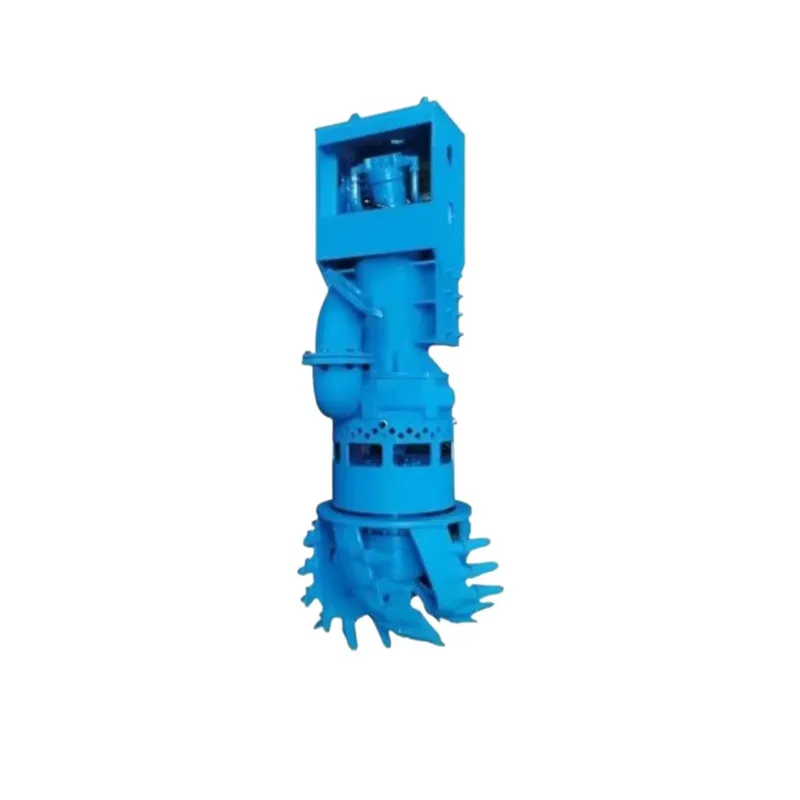

Elecric Submersible Dredge Pump with Cutter Head

This electric dredge pump is powered by electricity and is designed to be submerged underwater.

The cutter head is attached to the pump and is used to break up and dislodge sediment, debris, or other materials from the seabed or riverbed.

Hydraulic Submersible Dredge Pump with Cutter Head

Hydraulic submersible dredge pumps are powered by hydraulic systems, often from a hydraulic power pack or excavator.

The cutter head attached to the hydraulic pump is used for cutting and loosening material during dredging operations.

Cutter Head Types

Side Cutters:

Side cutters are additional cutting mechanisms mounted on the sides of the dredge pump or dredging equipment.

These cutters help widen the dredging path and increase the efficiency of material removal.

Side cutters are particularly useful in situations where the material being dredged is compacted or difficult to dislodge.

Central Cutter:

A central cutter is a cutting mechanism located at the center of the dredge pump or attached to the suction head.

It’s designed to break up and loosen material directly in front of the pump intake.

Central cutters are effective for dredging operations where the material is heavily compacted or where precision cutting is required.

Cutter Head Advantage

-

Breaking up of Sediment: In many cases, the material being dredged is compacted or consolidated, making it difficult to pump efficiently. The cutter head is equipped with sharp blades or teeth that help to break up this compacted sediment, making it easier for the pump to suction and transport the material.

-

Preventing Clogging: Without a cutter head, submersible dredge pumps are prone to clogging, especially when dealing with dense or fibrous materials such as mud, sludge, or vegetation. The cutter head helps to shred and disperse these materials, reducing the risk of clogs and ensuring continuous operation.

-

Increased Efficiency: By breaking up sediment before it enters the pump, cutter heads improve the overall efficiency of the dredging process. They reduce the amount of energy required to pump material and minimize wear and tear on pump components, ultimately leading to cost savings and higher productivity.

Sand Dredge Pump Application

Mining

Mineral extraction, excefficiently lifting valuable resources like ore sand,gold, and diamonds from underwater deposits

Dredging

Remove sand,slurry,sediment, silt, and debris from bodies of water to maintain navigable waterways, ports

.

Desilting

Rivers, lakes and reservoirs clean up,effectively remove sand,slurry,tailings and other solid

Industry

Handle abrasive fluids with solid,such as sand, ash slurry,coal slurry, chemical slurry and sediment

Applications of Everflowing Submersible Sand Dredge Pump

Dredging and Excavation: Widely used in dredging projects, these pumps remove impurities from rivers, lakes, and ports, playing a crucial role in maintaining waterways and reclaiming land. Their powerful suction capacity enhances dredging efficiency, even in deeper waters.

Mining and Mineral Processing: These pumps improve extraction efficiency and offer excellent wear resistance, making them vital in the mining industry for handling slurry containing solid particles.

Construction and Infrastructure Development: Used to remove water, sediment, and debris from construction sites, these pumps facilitate safe and efficient construction operations and are essential in infrastructure projects like bridges, tunnels, and dams.

Power Generation: Everflowing Submersible Dredge Pumps handle mortar efficiently, making them essential in thermal power plants for transporting ash from coal burning without blockages or other issues.

Industrial and Process Applications: These pumps find applications in various industries requiring pumping of abrasive slurries, including cement production, steel manufacturing, chemical processing, and wastewater treatment.

Get Your Custom Dredging and Pumping Solution

Work Video

Submersible Sand Dredge Pump Installation

- Vertical Installation: The submersible dredge pump is positioned vertically in the water column, usually suspended from a support structure or anchored in place. This installation type is often used in deep water or where the pump needs to reach a specific depth for efficient dredging.

- Automatic Coupling Installation:Mounting the coupling device at the bottom of the pool, allowing the pump to slowly descend along the guide rails until it is connected to the discharge pipe socket via the coupling flange.

- Floating Installation: The submersible dredge pump is mounted on a floating platform or vessel. This installation type allows for mobility and flexibility in dredging operations, especially in large water bodies or when dredging in different locations is required.

- Excavator Installation: The submersible dredge pump is installed using an excavator. This installation type is often used in smaller-scale dredging projects or in locations where access is limited, such as narrow waterways or remote areas.

The choice of installation type depends on factors such as water depth, site accessibility, project scale, and specific dredging requirements. It’s essential to carefully evaluate these factors and select the most suitable installation type to ensure efficient and successful dredging operations. Additionally, consulting with experienced dredging professionals and adhering to industry best practices can help ensure the optimal performance of the submersible dredge pump in the chosen installation type.

About Us

Everflowing Pumps is a leading dredging and mining machine manufacturer .we focus on sand dredge pump,slurry pump,water pump,excavating,dredging and mining machine.We design and supply practical solutions according to customers’ technical requirements and work sites.Our products enjoy good popularity and have such features as exquisite workmanship, reliable performance and excellent quality.

Our products enjoy good popularity everywhere and have such features as exquisite workmanship, reliable performance and excellent quality. Our products are popular in domestic and overseas markets and are exported to America, Russian, Ukraine, Indonesia, Malaysia, Korea, Nigeria and other countries and regions. We have gained trust and good recognition from our customers.

We always focus on our customers’ needs and always improve and update our products to meet customers’ requests and the local terrain environments, such as making and designing new model products. We are fully committed to perfect and unique products, consummate customer services and the reputed commercial credit of satisfying customers unremittingly.

Send InquiryWhy Choose Us

More than 20 years experience in dredging and mining

One stop solution for dredging and mining

Free design. Consulting now saves 30%

Exported to more than 60 countries

Custom solutions, contact immediately

Professional and Advanced Equipment

With more than ten years of experience in product manufacturing. Professional technicians provide you with professional advice. Advanced equipment creates high-quality products for you.

Low Price and High Quality

One stop service can reduce costs and improve quality standards. Arrange from design, material, processing, delivery time, quality inspection and transportation. Reduce any additional costs throughout the process.

Fast and Convenient Delivery

Fast production, early delivery, reliable logistics, can provide door-to-door service. Various transportation modes meet different countries.

Best After-sales Service Provided

Improve product sales and technical after-sales service. 24 hours online video call, actively solve problems for customers

Get Your Custom Dredge Pump

Everflowing is a trusted manufacturer of sand dredge pump with more than 20 years experience in creating high-quality dredging solutions for various solid. It specializes in manufacturing high-quality custom submersible slurry pump to cover various needs of customers. Here are your custom selections:

Support

1. Product selection, program design

According to the project, select the appropriate products and design the construction program

2. Customized personalized products.

3. Technical service

Real-time online support including email, chat to assist in responding to customer queries.

4. Installation and commissioning services can be provided for some products as needed.

5. Long-term provision of accessories, technical support.

FAQ

A dredge pump is a type of pump used to extract material, typically sediment or debris, from the bottom of a body of water or other shallow waterway. Dredge pumps are commonly used in dredging operations, which involve the removal of material from the bottom of rivers, harbors, and other bodies of water to improve navigation or to extract valuable resources such as minerals or oil.

Dredge pumps typically use centrifugal force to move water and the sediment or debris that it contains. They are designed to handle high volumes of water and solids, and they are often equipped with heavy-duty impellers and wear-resistant materials to withstand the harsh conditions of dredging operations.

Dredge pumps come in a variety of sizes and configurations depending on the specific requirements of the dredging operation. Some pumps are mounted on barges or other vessels, while others are portable and can be moved from one location to another.

A dredge pump is a type of pump used in dredging operations to remove material such as sediment, sand, and other debris from the bottom of bodies of water like rivers, lakes, and oceans.

The dredge pump works by creating suction or using an impeller to move water and sediment from the bottom of the water body into a pipeline or other container. The material can then be transported to a different location or disposed of as needed.

Dredge pumps come in various sizes and types, depending on the size and nature of the material being dredged, as well as the distance it needs to be transported. They can be powered by electricity, diesel engines, or hydraulic systems, and can be mounted on a variety of vessels such as barges, dredgers, or excavators.

Overall, dredge pumps are an essential component of many dredging operations, and they help to keep waterways clear and navigable, support marine construction projects, and protect coastal communities from erosion and flooding.

A dredge pump is a type of centrifugal pump used to transport sand, mud, and other solids in mining, construction, and environmental applications. The pump works by converting mechanical energy from a motor or engine into fluid energy, which moves the dredged material through a pipeline or hose.

The dredge pump consists of an impeller, volute casing, and suction inlet. The impeller is a rotating component with curved blades that spin inside the volute casing, which is a stationary housing that directs the flow of fluid. The suction inlet is a port where the material enters the pump.

When the impeller rotates, it creates a centrifugal force that moves the fluid and solids outward from the center of the impeller. This force creates a low-pressure zone in the center of the impeller, which draws the material into the pump through the suction inlet. As the material enters the pump, it is mixed with the fluid and moved towards the volute casing.

Once the material reaches the volute casing, the fluid and solids are directed towards the discharge outlet, where they exit the pump and are transported through the pipeline or hose. The discharge pressure of the pump depends on the design of the impeller and volute casing, as well as the speed of the motor or engine driving the pump.

The distance that a dredge pump can transport sand depends on several key factors. Here are some important considerations:

Dredging Depth: Dredging depth refers to the depth at which the pump extracts sand from the surface to the seabed.

Sand Characteristics: The nature of the sand being dredged is crucial. Depending on the particle diameter and density of the sand, finer sand may be pumped over longer distances compared to coarse or heavy sand.

Sediment Concentration: The concentration of sand and sediment in the water will affect the pump’s transport distance.

Altitude Changes: Significant changes in altitude along the transportation route can impact the pump’s transport distance. For example, pumping sand uphill requires more energy and may limit the distance.

Pipe Diameter and Material: Different pipe materials and diameters used for transportation result in varying friction and resistance, affecting the transport distance.

Dredge Pump Type: The type of dredge pump used plays a crucial role in determining its sand transport distance. High-head dredge pumps can transport sand over longer distances.

Dredge Pump Size and Power: The size and power of the dredge pump also influence its sand transport capacity. Larger, more powerful dredge pumps can transport sand over greater distances.

Everflowing dredge pump

Cost effective

Start Dredging on a Budget

Fulfil your sand dredging dream with Everflowing dredge pump

Contact:

WhatsApp:18186915181