Sand Pump

Efficient Solution for Pumping Abrasive Materials

Sand pumps are specially designed to pump sand and other solid materials from sources such as mines, rivers, and oceans.

These pumps are highly suitable for applications involving highly abrasive materials with large capacity requirements.

Main Applications of Sand Pumps

-

Mining: Extraction of sand from quarries and transportation of tailings.

-

Marine Engineering: Land reclamation, pumping of marine sand, cleaning of pile holes for offshore wind turbines, and trenching for submarine cable installation.

-

Dredging: Dredging of rivers, waterways, ports, and harbors to maintain required depths and ensure smooth navigation.

-

Construction: Cleaning of bridge pile foundations, offshore wind turbine pile holes, building foundation pits, as well as removal of sand and mud from caissons and steel sheet pile walls.

-

Municipal Engineering and Wastewater Treatment: Removal of sediment from wastewater ponds, sedimentation tanks, and similar facilities.

-

Industrial Sectors: Transportation of steel slag, blast furnace slag, coal slime, sand, and other slurries in steel mills, coal mines, coal washing plants, power plants, and sand washing operations.

Sand pumps offer the key advantage of high-capacity handling of highly abrasive materials. Using sand pumps to transport sand is an efficient and cost-effective method that boosts production efficiency while significantly reducing operational costs.

MAIN CHARACTERISTICS

Stable and Reliable

Equipped with a higher-power motor configuration to prevent overload failures and minimize unplanned downtime to the greatest extent possible.

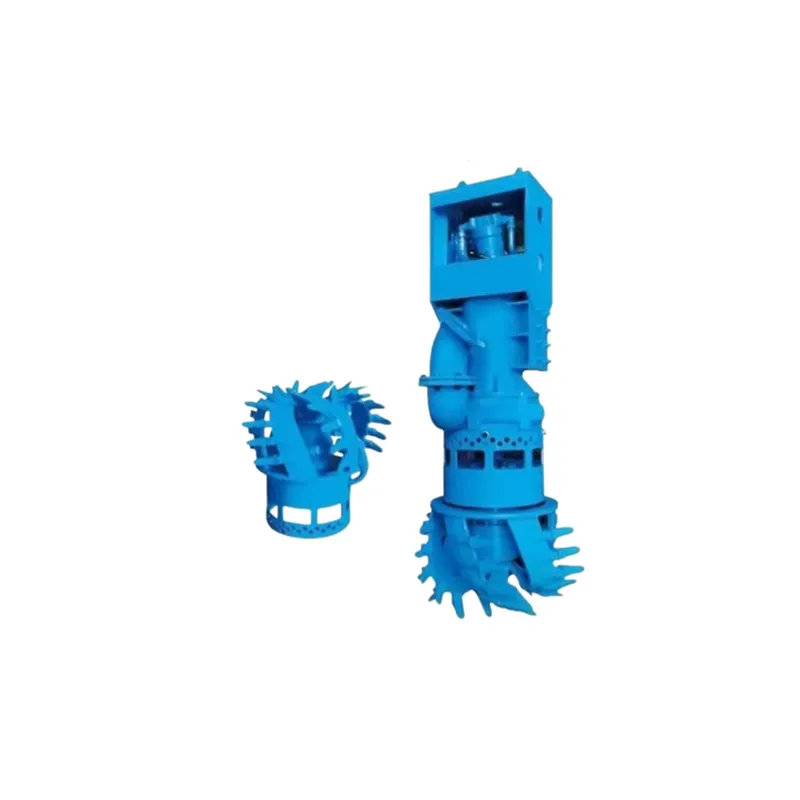

Deep-Water Submersible Design

Maximum submersion depth of 150 meters, tailored for deep-water applications.

High-Strength, Wear-Resistant Wet-End Components

All wetted parts are made of premium high-strength, abrasion-resistant materials for extended service life.

Wide, Non-Clogging Flow Passage Design

Broad impeller and volute passage to effectively prevent blockages and ensure smooth operation with high solids content.

High Head, Long-Distance Pumping Capability

Delivers high discharge head, enabling efficient long-distance transportation of abrasive slurries.

Electric Sand Pump

Hydraulic Submersible Sand Pump

Everflowing Sand Pump

Purpose-built for Sand Mining & Dredging

Reliable,Durable and Affordable

Sand pumps are specially designed for pumping sand from mining.

pumping sand from rivers, seas, etc.

Construction sand is a building material in high demand. Using a sand pump to pump sand is an efficient and economical method.

Mining: mining sand and tailings transportation

Marine engineering: land reclamation, infrastructure construction of docks and offshore structures.

Dredging: dredging rivers, waterways, ports, and docks.

Construction: Cleaning foundation pits, caissons, and steel sheet piles.

Municipal engineering, sewage treatmen: sediment cleaning in sewage pits, sedimentation tanks, etc.

Industrial enterprises: transportation of steel slag, water slag, coal slime, in steel plants, coal mines, etc.

Sand washing field, coal washing plant: transportation of sand, coal slime, and other slurries

What Are The Problems With Sand Pumping and Dredging?

Sand and gravel is abrasive,which can cause premature wear and reduced efficiency in pumps that are not designed for the heavy-duty operation. Additionally, the corrosive nature of these materials can cause equipment damage over time, requiring frequent repairs and maintenance. High-density suspended solids in pumped fluids may cause blockage of pumps and pipes. This creates additional challenges when pumping these materials.

Wear-resistant and Non-clogging

Reducing Downtime and Maintenance Costs

Your Reliable Sand Pump Machine Manufacturer

However, the Everflowing Sand Pump offers solutions to these challenges with its innovative design. Everflowing sand pumps are manufactured from highly wear-resistant materials to handle sand and gravel with ease, and their unique wide flow channel design allows for pumping higher solids contents.

Unlike traditional centrifugal pumps, the Everflowing Sand Pump is anti-wear and anti-clog, reducing downtime and maintenance costs. Ensure efficient and reliable operation, minimizing downtime and costly repairs

Everflowing Pumps is a trusted sand pump machine manufacturer with more than 20 years experience in creating high-quality dredging solutions for various industries.

Our sand pump machines come in a range of sizes and designs to meet your unique needs and budget. From small sand pump machine to large custom-designed sand pump machine, we offer a wide range of options to choose from.

Our experienced designers and engineers leverage the latest technologies to create sand pump machines for dredging. We use different types of sand pumps,platform, power pack to make sure that our sand pump machines stand out from the competition.

Efficient and Cost-effective Pumping Sand Solution

Pumping sand through pipelines offers a significantly more efficient and cost-effective solution compared to traditional truck transportation methods.

Advantages

- Speed and Efficiency: Pumping sand through pipelines allows for a continuous flow of material, which significantly speeds up the transportation process compared to trucking. Trucks have limited capacity and are subject to traffic congestion, road conditions, and loading/unloading times, whereas pipelines can transport large volumes of sand consistently and quickly.

- Reduced Labor and Equipment Costs: Operating a pipeline system for sand transportation requires fewer laborers and equipment compared to managing a fleet of trucks. With pipelines, once the infrastructure is in place, the process becomes largely automated, reducing ongoing operational expenses.

- Lower Environmental Impact: Pumping sand through pipelines produces fewer emissions compared to truck transportation, contributing to lower carbon footprint and reduced air pollution. Additionally, pipelines minimize land disturbance and habitat destruction associated with building and maintaining roads for truck transportation.

- Cost Savings: Over the long term, pumping sand through pipelines can result in significant cost savings compared to truck transportation. While the initial investment in pipeline infrastructure may be higher, the lower operational costs, reduced maintenance, and longer service life of pipelines often outweigh the expenses associated with truckin

Types of Sand Pump Machine

Sand pumps are the most effective equipment for sand mining operations, dredging projects, sand hydraulic transportation. Sand is carried by the flow of water to transport solids through pipes and often involves working in sensitive or harsh conditions. The sand suction pump has the characteristics of high efficiency, wear resistance, and long-distance transportation, and is very suitable for sea sand, river sand, ore sand, mud, sludge and other objects.

Efficient Horizontal Sand Pump for Reliable Sand Suction

Get a free quoteHorizontal Sand Gravel Pump

What is the best pump for pumping sand?

Efficient Horizontal Sand Pump for Reliable Sand Suction

Get a free quoteHorizontal Sand Gravel Pump

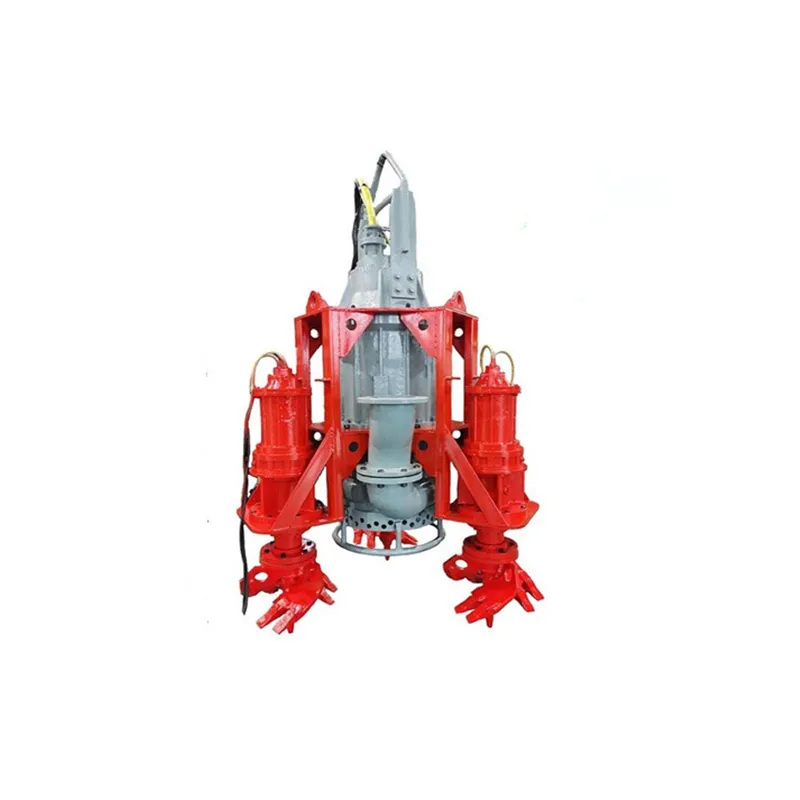

3. Excavator-Mounted Sand Pump

Pump Type: Excavator-Mounted Sand Pump or Hydraulic Submersible Sand Pumps.

Hydraulic Power: The pump should be compatible with the excavator’s hydraulic system.

Application: For excavation projects that require direct sand pumping from pits, rivers, or lakes, sand pump mounted on an excavator is a powerful and efficient solution.

Advantages:Excavator-mounted pumps allow for easy maneuverability and precise control, as the pump can be directly lowered into the area being dredged. Hydraulic submersible pumps, powered by the excavator’s hydraulic system, offer powerful sand pumping capabilities in challenging environments. They often come with an agitator or cutter head to loosen and stir up sand for efficient pumping.

Choose Suituable Sand Pump Accoding to Power

Supporting Power

Industrial electricity or generators can power sand pumps. Alternatively, diesel engines or hydraulic stations can be used.Installation Type

There are different of sand pumps installation types to choose from, Each type has its advantages and limitations.

High Head Dredge Booster Pump

Get a free quoteHow to Choose Suituable Sand Pump ?

Sand Pump Application

Everflowing sand pumps are ideal for a variety of applications, including dredging rivers, canals, lakes, ponds, reservoirs, dredging ports, wharfs, dredging sand from tailings, removing slag and dust from steel plants, power plants, coal mines, etc.

Mining

Mineral extraction, excefficiently lifting valuable resources like ore sand,gold, and diamonds from underwater deposits

Dredging

Remove sand,slurry,sediment, silt, and debris from bodies of water to maintain navigable waterways, ports

.

Desilting

Rivers, lakes and reservoirs clean up,effectively remove sand,slurry,tailings and other solid

Industry

Handle abrasive fluids with solid,such as sand, ash slurry,coal slurry, chemical slurry and sediment

Work Video

Why Choose Us

More than 20 years experience in dredging and miningOne stop solution for dredging and mining

Free design. Consulting now saves 30%

Exported to more than 60 countries

Custom solutions, contact immediately

About Us

Everflowing Pumps is a world-leading manufacturer of sand pumps, specializing in the production and customization of various types of sand pumps to meet the diverse needs and requirements of our customers. Our expertise lies in developing sand pumps tailored to different operating conditions and specifications.

Support

1. Product selection, program design

According to the project, select the appropriate products and design the construction program

2. Customized personalized products.

3. Technical service

Real-time online support including email, chat to assist in responding to customer queries.

4. Long-term provision of accessories, technical support.

Sand Pump FAQ

Horizontal sand pump

Submersible sand pump

Vertical sand pump

Wet parts are made of high wear resistant alloy.

We offer a variety of standard dimensions for our sand pumps, including small, medium, and large sizes. However, we can also provide custom sizes as per the specific requirements of our customers.

Yes, we can provide custom sizes for our sand pumps. Our team of experts can work closely with customers to determine the appropriate dimensions based on their unique needs.

We offer wide range options for our sand pumps. Customers can also choose suituable pump depending on their work condition and requirements.