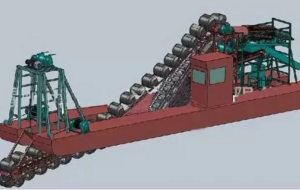

Submersible Dredger

The submersible dredger is an innovative underwater excavation and dredging equipment that operates beneath the water’s surface. Its design and components are optimized for effective removal and transportation of sediment. The submersible dredger features a submerged pump platform, equipped with a pump system, cutter mechanism, and control system. This platform enables the dredger to efficiently clear sediment underwater.

Structure of the Submersible Dredger:

Hull Design: The dredger’s hull is thoughtfully designed for underwater movement and operation. It includes watertight compartments to ensure buoyancy and stability.

Mobility System: The dredger can move forward, backward, left, and right through winches, and can also be equipped with propellers or thrusters. Lifting System: The sand pump is raised and lowered through a hoisting mechanism.

Pumping System: An electric or hydraulic submersible dredge pump operates on the principle of the impeller’s rotation creating a vacuum. Through the suction inlet, it draws water and sediment from the seabed.

Cutter Mechanism: The cutter is positioned near the suction inlet and consists of rotating blades that break down compacted sediment and debris on the seabed, facilitating easier material extraction by the pump.

Power System: A generator directly powers an electric pump, while a generator or diesel engine drives a hydraulic pump to power the dredge pump. Control System: It manages the operation of both the pump and the vessel.

Suction and Excavation: As the submersible dredger descends to the seabed, the cutter mechanism releases sediment. Simultaneously, the pump’s rotation generates a vacuum, drawing in a mixture of water and sediment.

Underwater Conveyance: Sediment is transported from the pump’s outlet through a flexible hose to the water’s surface. The pipeline’s design ensures it can withstand the wear caused by sediment.

Transport to the Land: The pump’s suction propels the mixture through the floating hose to the land.

Separation and Disposal: At the surface, a sedimentation tank or other separation techniques are employed to separate the mixture into water and sediment. The sediment settles, allowing clean water to be returned to the water body, while the sediment is properly managed or reused.

Tsubmersible dredger represents a sophisticated solution for underwater sediment removal. Its specialized structure, operational systems, and engineered pipeline facilitate efficient dredging operations below the water’s surface. Understanding its configuration and operation provides insight into the intricacies of underwater excavation processes, essential for maintaining waterways, infrastructure, and ecosystems.

Parmeter

| No | Model | Unit | YLQ01 | YLQ02 | YLQ03 | YLQ04 |

| 1 | Dredger body size (L*W*H) | m | 5.5×1.2×1.2

(2 PCS) |

8×1.2×1.2

(2 PCS) |

8×1.2×1.5

(2 PCS) |

10×1.2×1.5

(2 PCS) |

| 2 | Pump power | KW | 11~15 | 22~37 | 45~75 | 90~132 |

| 3 | Pump size | inch | 4/6 | 4/6 | 4/6/8 | 6/8/10 |

| 4 | Pump flow capacity | cbm/hr | 50~150 | 75~300 | 100~600 | 200~1250 |

| 5 | Max. passing gravel diameter | mm | 21 | 45 | 36 | 56 |

| 6 | Max. dredging depth | m | 25 | 25 | 25 | 25 |

| 7 | Max.Discharge distance | m | 300 | 600 | 900 | 1100 |

| 8 | Discharge pipe diameter | inch | 4/6 | 4/6 | 4/6/8 | 6/8/10 |

| 9 | General control Box (optional) | KW | 15-22 | 30-45 | 55-90 | 110-160 |

| 10 | Generator (optional) | KW | 30 | 45-75 | 90-150 | 120-320 |

| 11 | Other configuration | Operation room, Electric hoist, cable roller, winder, anchor, shelter, etc | ||||

| 12 | Cable length | Customize according to requestment | ||||

| 13 | Power Supply | Generator | ||||

| 12 | Remark | 1. Hydraulic system pump is available. 2. Generator power is affected by control box start way. 3. Max 3 pieces of extra agitator can be added. 4. Above data could be adjusted and customized according to your specific requirements. |

||||

Reviews

There are no reviews yet.