Manufacturer of Dredge Pump

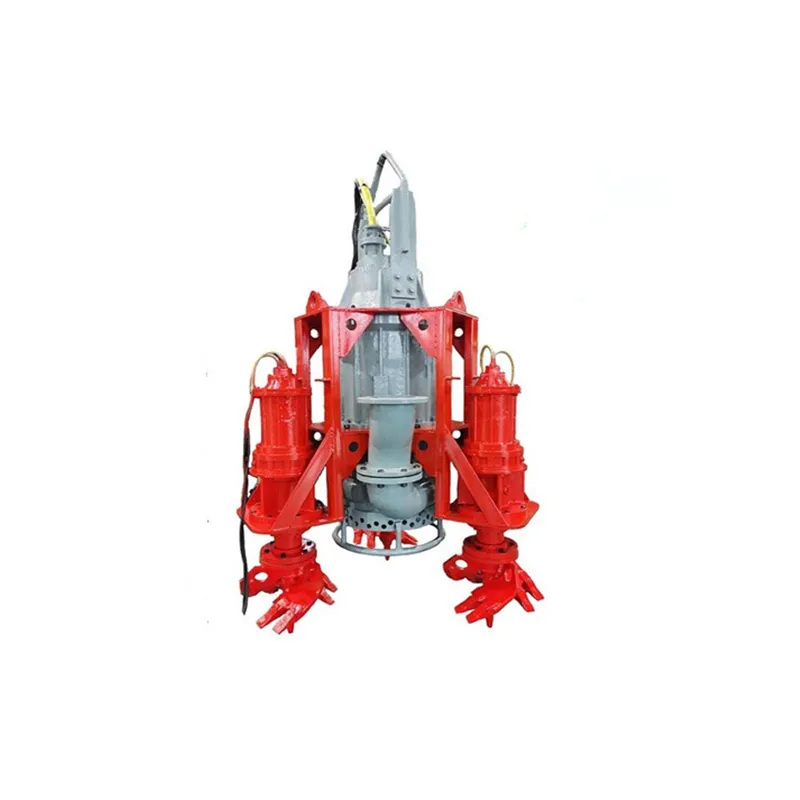

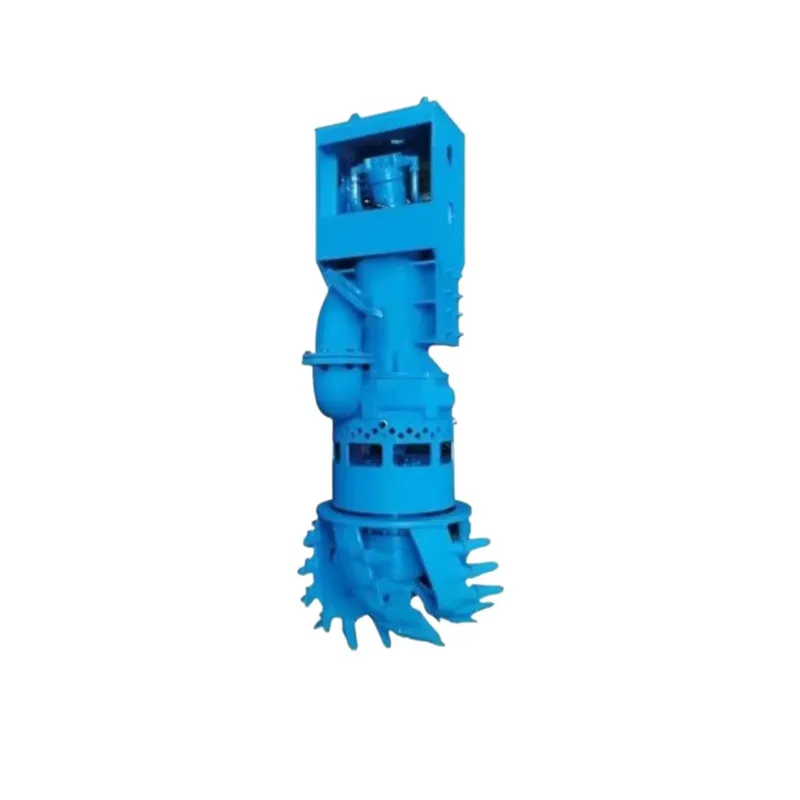

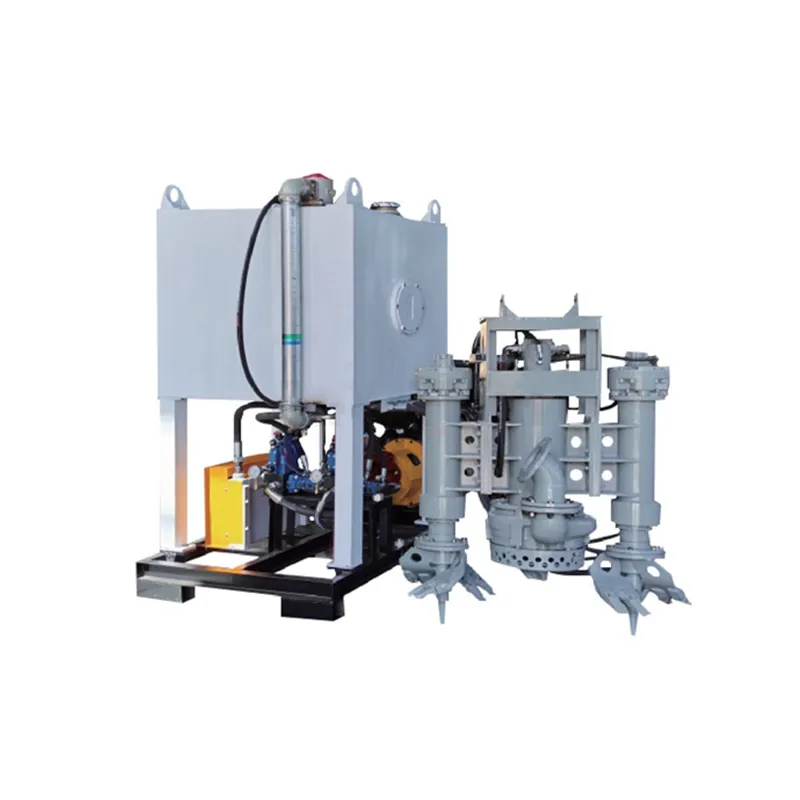

We are a professional dredge pump factory, specializing in the production of various types of dredge pumps. Our range includes horizontal dredge pumps, vertical dredge pumps, and submersible dredge pumps. We offer a variety of power options, including electric dredge pumps, diesel engine dredge pumps, hydraulic dredge pumps, and excavator mounted dredge pumps, catering to the diverse needs of our customers.

Our horizontal dredge pumps are designed for efficient and high-volume mud dredging operations, while the vertical dredge pumps are suitable for applications where space is limited. The submersible dredge pumps are ideal for underwater dredging tasks. We take pride in delivering reliable and robust equipment that can handle even the toughest of dredging challenges.

Send Inquiry